Plastic Injection Disposable Tableware Food Container Mold Supplier

Basic Info.

| Model NO. | RJTWB78 |

| Mould Cavity | Single Cavity |

| Plastic Material | PP |

| Process Combination Type | Single-Process Mode |

| Application | Household Appliances, Commodity, Home Use, Food Storage |

| Runner | Hot or Cold Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | TS16949, CE |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | 1 Year |

| Mold Spares | Ejectors/Water Tips/Rings/Seal Rings/Heater etc |

| Mold 3D Type | STP/Step/X-T/Igs |

| Delivery Time | 50 Days |

| Mold Life | 0.6 Million Shots |

| Transport Package | Wooden Box |

| Specification | Customized |

| Trademark | OEM/ODM |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 20 Sets/Year |

Packaging & Delivery

Package Size 500.00cm * 200.00cm * 200.00cm Package Gross Weight 300.000kgProduct Description

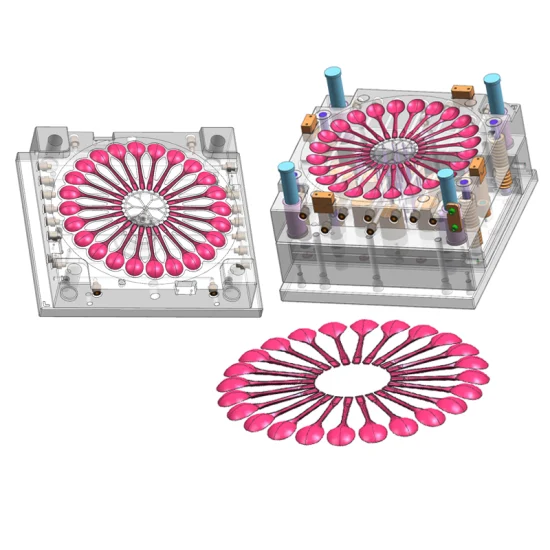

Thin Wall Container Mould

RJ Mould has been actively involved in the plastic thin wall mold industry for the past ten years. Our factory has different four departments, includes mould design, mould manufacturing, mould quality control and foreign sales department. All the honest and hard-working people with good technology formed a group of skilled, high-quality team. The professional team at RJ mould is ready to offer you the best service and qualified moulds and on-time delivery.

Our current thin-wall products include Bubble tea cups, food packaging containers, disposable cups and containers, plastic spoon and so on.

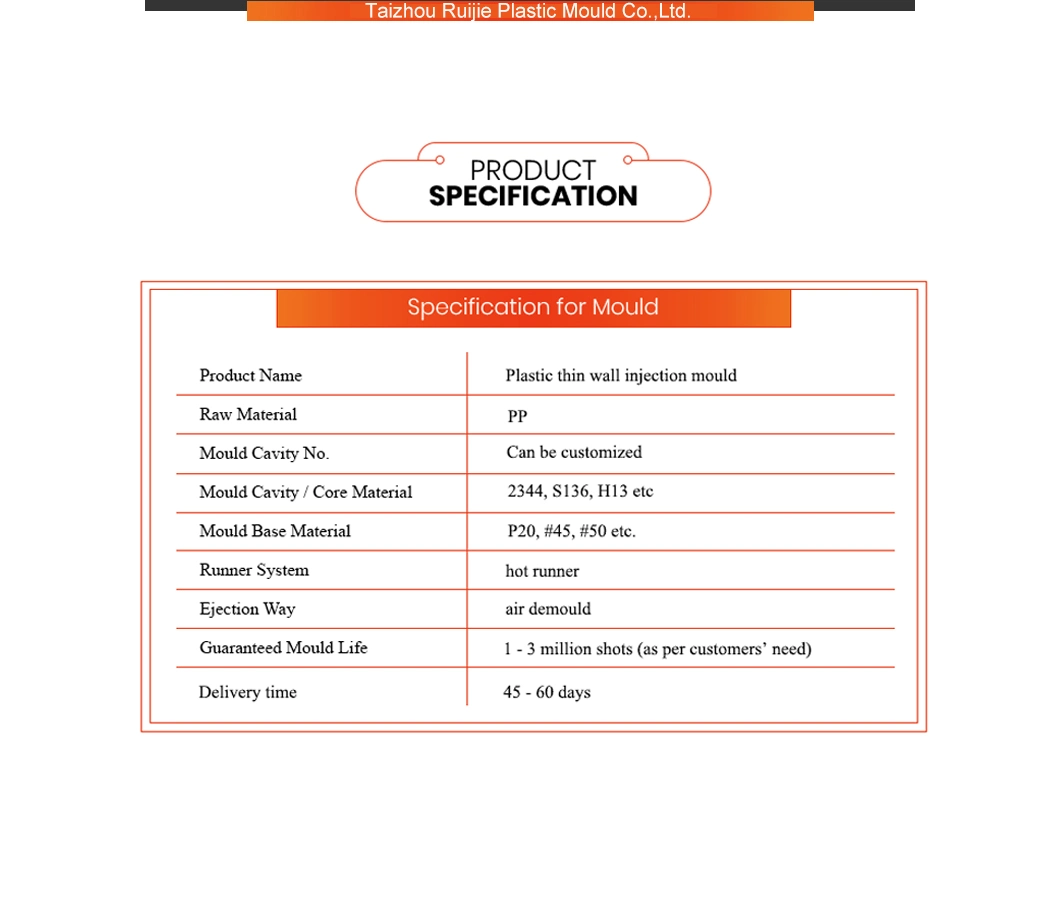

Suitable steel material for Thin wall mould

The common mold steel adpots on thin wall mould is P20, 2738, H13, NAK80, 2316, 2344, S136 etc. Through reasonable heat treatment methods, the steel can achieve higher hardness and can ensure a longer mould life.

Why choose us for Thin wall mould?

1. Select suitable steel material for each part of mould.

2. High-precision machining process.

3. Effective cooling system.

4. Separate cavity molding inserts locking system for multi-cavity thinwall container mould.

5. High-speed injection molding system.

Thin wall plastic food container mould

Square shape thin wall fruit vegetable container mould1. Food container size can be customized

2. Shape: square

3. Wall thickness is 0.5-0.6mm.

4. Weight: As per customers' need

Key Points of our thin wall moulds

Top quality steel material is always used on our thin wall container moulds, S136 and H13 steel materials are the most ideal. Steel hardness after vacuum hardening can reach HRC 45-52.By using the best cooling system and adopting with BeCu to help the mould cooling, our thin wall container mould cycle time is 4 - 6 secords per shot.

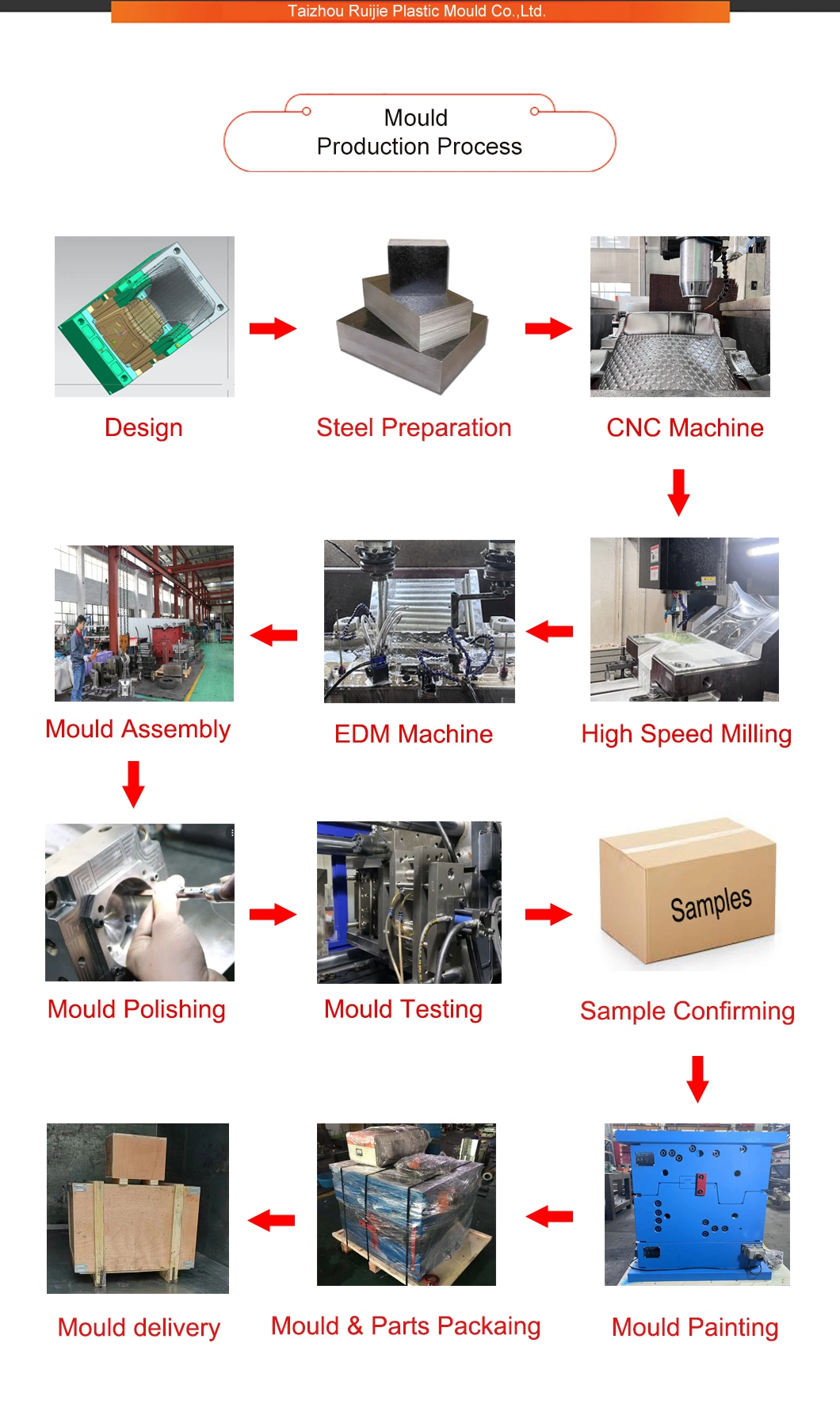

Other Thin Wall MouldsOur Mould Production Process

1Q: Are you trading company or manufacturer ?

A: We are factory and located in Taizhou City, Zhejiang Provice, China.2Q: What kind of service do you offer?

A: We can make all kinds of plastic injection moulds. Customized mould project are also welcomed in RJ Mould.Besides, we have our own injection machine and can do mass production for customers too.3Q: What information is required for a quote? A. Please provide us with product 2D or 3D drawing.If you don't have drawings on hand, samples are also available for checking cost.4Q: Can I have my own design?

A: Yes, we are very capable to do customized design and make for you. Please share with your ideas, we will discuss your needs, purpose and objective thoroughly and work together with you for the whole project.5Q: How long is your delivery time?

A: The lead time of T0 sample depends on the mould structure, and generally it takes 20-70 days from receipt/approval of final drawings, deposit and mold design approval.Mass production delivery time depends on the order quantity.6Q: What's your payment condition?

A: For Mould: T/T, 40% Deposit with P.O., balance before shipment. Or 100% irrevocable LC at sight.Part molding: 50% after PO confirmed, 50% after production finished.7Q: What Hot Runner Brand will you use?

A: As per customers' demands, we can offer YUDO or Chinese local brand hot runner system.8Q: What's your injection mould life?

A: 0.5 to 3 million shots guarantee, depends on your needs.9Q: What's the shipping cost? And how long it takes for shipment?

A: Please let us know,1. Shipment method, do you prefer by sea or air?2. Destination port or door to door address with ZIP code.We will check and find the best price for you.