Ss Cookware Kitchenware Tableware Mold Gy1206

Basic Info.

| Model NO. | GY1206 |

| Manufacturing Technology | Computer Technology |

| Driving Motor Type | Permanent Magnet |

| Mold Cavity Technology | The Traditional Forming Electrode Machining |

| Milling Speed | High Speed |

| Parts Detection Method | Measurement of Three Axis NC |

| After-sales Service | Before & After Sales |

| Service 1 | Offer Tech. to Our Customers |

| Service 2 | Customer′ Workers Learn at Our Factory |

| Expert Years | 25 + Years Expert Experience |

| Advantage of Our Mold 3 | Advanced Machine for Making Mold |

| Advantage of Our Mold 4 | China/World Largest Ss/Alu.Copper Cookware Product |

| Advantage of Our Mold 2 | Durable Material |

| Advantage of Our Mold 1 | Professional Mould Machine Team |

| City | Largest Ss Cookware Production City in China |

| Service | China Newest Tech.Design Sharing |

| Install Way | Videos & Oversea Installing Training |

| City We Are in | Chaozhou City |

| Solution | a-Z Solution |

| Transport Package | Non-Fumigation Wooden Box |

| Specification | Customized |

| Trademark | QuanZheng Brand |

| Origin | Guangdong Province China |

| Production Capacity | 80 Sets of Molds Per Month |

Product Description

Our Advantages

Our factory locates in Chaoshan,which is the largest cookware production base in China/ the world.

Not only do we have experience of producing machines and moulds, we also have theexcellent pratical experience of producing cookware.

It is the big difference between us and other city's trade companies.

| Material | Cemented Carbide, Cr12mov,Bearing Steel & A3 Iron | Brand | Quanzheng Brand |

| Making Tech. | Computer Technology | Specification | Be Customized |

| Process CH. | Drawing Dies | Origin Country | China |

| Application | Hardware ( ss , alu. copper or other ) | Solution | A-Z Solution |

| Degree Process | Composite Mold | Service 1 | Newest Tech. Design Sharing |

| Cavity Tech. | Germany CNC High Level Machine | Service 2 | Professional Team Video Teaching |

| Milling Speed | High Speed | Service 3 | Customer's workers Learn In Our Factory |

| Part Testing Way | Measurement Of Three Axis NC | Service 4 | Factory Layout Flowchart Design |

Product Description

Mould instructions:

Drawing (stretching) mold material selection of national standard brand steel,(CR12mov) hard alloy, commonly known as Tungsten steel, good performance, wear resistance, not easy to have stretching marks, molds for stainless steel, aluminum, copper plate Tableware and kitchenware products.1. Professional Mould Team

- Our Chief Mould Expert has more than 16 years mould making experience.

- Our factory has a strong ,experienced mould design, making engineer team.

- Since the excellent,top-level experience in China, our engineer team was invited to exchange tech.by the Egypt's Ministry Industry.

2. Durable Material

- We use the best quality material to make mould.

- Normal using,no error operation ,our mould service life is more than 10 years.

- One of our customers in our city has used our mould more than 20 years now.

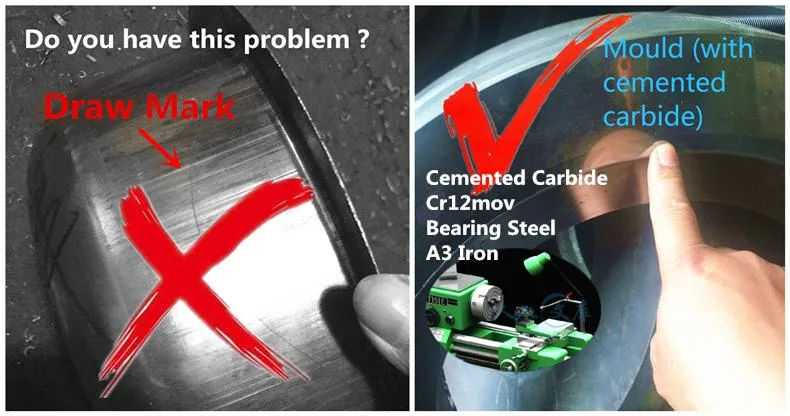

* Do you have the problem ?

The fainful ugly draw marks appear after your new draw moulds be press about 1000-3000 times.

Our engineers team use the best quality material ( Cemented Carbide,Cr12mov,Bearing Steel & A3 Iron ) to making mould with our advanced mould making machines and experience.

3. Advanced Machines For Making Mould

- We have the most advanced mould making machines.

- Only advanced machines & excellent,top-level experience, can make good mould.

4.World's Largest SS/Alu./Copper Cookware Production Base

- Our city is the Largest Cookware Utensil production line in China/ the world.

- More Factories, More Feedback, More Exp., More Advanced.

Our Services

Steps:

1.Draw/Photos,Material,Dia,Length,Width,Height,Thickness to us.

- Material: Stainless steel 304,430,210,Copper,Aluminum,Iron,Enamel...ect.

- If ok,send more detailed photos to us.The edge,bottom,polishing situation ect.

- Do you have any producing experience?

- Do you have any machines ? Hydraulic press machine ? Punch ? How many tons of them ?

- It is better to send sample to our factory.

2.Our engineer team discuss and calculate your item/sample.

3.We make a detailed Product Line Project & Price List to you.If ok,place order to us.

4.If need,you visit our factory.If ok,place order to us.

5.We make moulds and machines.

- According customer's request, we make moulds and machines.

- After making moulds and machines,we will take trial production,take videos to you.

- We will send trial production samples to you to comfirm.

6.If need, we will offer oversea Installing Training.