China Plastic Injection Mould Facotry Customize Plastic Pail Paint Bucket Injection Mould

Basic Info.

| Model NO. | HC-Bucket Mould35 |

| Application | Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware |

| Runner | Hot Runner |

| Design Software | UG |

| Installation | Fixed |

| Certification | ISO |

| Standard | HASCO |

| Customized | Customized |

| After-sales Service | Good After-Sales Service |

| Mould Running | Full Automaticity / Semi Automaticity |

| Mould Standard | Dme/Lkm/Hasco |

| Mold Hot Treatment | Quencher, Nitridation, Tempering,etc. |

| Production Machine | Plastic Injection Molding Machines |

| Shipping Time | 35-55 Working Days |

| Mould Steel | P20,2738,718h,Nak80,2316,S136,H13,etc |

| Mould Surface Treatment | EDM, Texture, High Gloss Polishing |

| Offer You | OEM & ODM Service |

| Tooling Machine Equipment | CNC Milling Machine/ Wire Cutting Mchine/ Drilling |

| Transport Package | Wooden Cases |

| Specification | Paint Bucket Molds |

| Trademark | Hongchuan Mould |

| Origin | China |

| HS Code | 8480719090 |

| Production Capacity | 150 Sets Per Year |

Product Description

China Plastic Injection Mould Facotry Customize Plastic Pail Paint Bucket Injection Mould

Hongchuan Mould is a highly reputable and experienced manufacturer of plastic injection molds, specializing in a wide range of products including household molds, furniture molds, and industrial molds. With a commitment to quality, precision, and innovation, we have become a trusted partner for clients worldwide.

Plastic Paint Bucket MouldPP Food Bucket MouldLubrication Oil Pail MouldSquare Bucket MouldRectangular Bucket MouldPE Pail Bucket Mould..........................

Our portfolio includes a diverse range of molds such as chair molds, table molds, bucket molds, basket molds, dustbin molds, storage box molds, baby bathtub molds, flowerpot molds, crate molds, washbasin molds, drawer molds, stool molds, baby set molds, laundry basket molds, pallet molds, trash can molds, spoon molds, knife molds, fork molds, thin wall box molds, and cap molds. Our team of highly skilled technicians and engineers is dedicated to designing and producing molds that meet the most demanding specifications.

Hongchuan Mould offers a wide range of plastic bucket mold designs. They are designed for injection molding buckets that are applicable in both food and non-food industries.On size, we can design a bucket mold that is small enough for a 1-gallon plastic bucket or big enough for a 5-gallon plastic bucket. We are also fully capable of developing custom bucket molds for other sizes within this range.Our shape options, on the other hand, include oblong, square, rectangular, and round plastic buckets. Additionally, our design team can incorporate other features including plastic pails with lids and IML (In Mould Labeling) buckets.Our plastic paint bucket mould, thin wall container mould and paint pail mould cover 0.5L,1L,3L,5L,10L,18L,20L,25L and Beryllium Copper(BeCu) for cooling.The beryllium copper on the core top and cavity neck lead to a very good cooling for the mould,and our latest deisgn for the core and cavity would prelong the mold life:the original paint bucket mould alignment and lock system is a round one,while we design an octagon step to have a better alignment and lock for the core and cavity,also which change would prelong the paint bucket mould life.

Hongchuan Mould's Plastic Bucket Injection Moulds - the ultimate solution for high-quality and durable plastic buckets. As a leading manufacturer in the plastic molding industry, we specialize in delivering top-notch molds that cater to the diverse needs of various industries. Our precision-engineered molds are designed to produce buckets with superior strength, excellent functionality, and exceptional aesthetics. With our advanced technology and commitment to customization, we offer tailored solutions that meet your specific bucket manufacturing requirements.Superior Strength and Durability: Our plastic bucket injection molds are constructed using premium-grade materials, ensuring outstanding strength and durability. The resulting buckets can withstand rigorous usage, heavy loads, and harsh environments while maintaining their structural integrity.Optimal Functionality: We prioritize functionality in our mold designs, creating buckets that are easy to handle, stack, and pour. Our molds incorporate features such as comfortable handles, reinforced bottoms, and precise spouts to enhance usability and convenience.Aesthetic Appeal: We understand the importance of visual appeal in product packaging. Our molds produce buckets with clean lines, smooth surfaces, and attractive designs. With customizable options, you can choose colors, textures, and branding elements that align with your brand identity.Customization Options: We offer customization options to tailor the plastic bucket molds to your specific requirements. Whether it's adjusting capacity, lid designs, or incorporating special features, our expert team will collaborate with you to create molds that align perfectly with your production needs.Precision Engineering: With our advanced technology and meticulous craftsmanship, we ensure precise molding of the plastic buckets. Our molds deliver consistent results, achieving tight tolerances, and smooth finishes for a high-quality end product.

| Material | new or recycled polypropylene (PP), polyethylene (PE). |

| Style | round, oval, square, rectangular… nested, straight-side… |

| Volume | from 1 L to 3 L, 1 gallon to 5 gallon… |

| Decorations Way | In mould labeling (IML), heat transfer printing, digital print… |

| Style | round, oval, square, rectangular… nested, straight-side… |

| Properties: a. Strength - durable for loading paints. b. Static and dynamic loading capacity requirement. c. Sealing property - guarantee the paints quality and transport. d. Stacking - to save storage room and easy for transport. e. Antistatic agent - prevent from dust and dirt. f. UV protected - as the storage and transport requirement. g. Filling paint temperature requirement. h. Reactions to chemicals - to ensure buckets are solvent-resistant and safe for use with all paints when it's necessary for test the possible reaction. | |

| Mould material | Hardness | Mould life |

| P20 | HRC 28-33 | >300,000 shots |

| 718 | HRC 33-36 | >500,000 shots |

| H13 | HRC >43 | >800,000 shots |

| 2344 | HRC >48 | >800,000 shots |

| S136 | HRC 48-52 | >1,000,000 shots |

| Mould Name | Plastic Turnover Crate Box Injection Moulds |

| Mold Meterial | P20,2738,718H,NAK80,2316,S136,H13,etc |

| Mold Base | Self-mad:LKM:DME |

| Runner | Cold runner and hot runner |

| Hot Runner Brand | Chinabrand:HASCO:YUDO and so on |

| Degsin Software | UG:Aoto CAD and so on |

| Mold Life | 50-500 million Shots/ 5-6 years, Even in 10 years in good maintenance |

| T1 Time | 45-60 days |

| Package | Wooden Case |

| Plastic Material | PP PC ABS PET PE PVC PMMA TPR PA6,PA66,ASA,POM,PS,ABS,ABS+GF,ABS+PC,POM(Derlin) |

| Warranty Period | 1 year or 1 million shot times(in this period, if the mold have problem, we will offer the parts or service by free, but not include the problems cased by wrong operation) |

| Mould Precision | +/-0.01mm |

| Mould Cavity | Single Cavity, Multi-cavity |

| Gate Type | Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate, etc. |

| Mould Surface Treatment | EDM, texture, high gloss polishing |

| Quality System | ISO9001,SGS,TS16949 |

| HS Code | 8480719090 |

| Origin | Made in China |

| Installation | fixed |

| Cavity | Single/multi |

| Specification | Depends on customer's requirements |

| Mold Cooling System | water cooling or Beryllium bronze cooling, etc. |

| Mold Hot Treatment | quencher, nitridation, tempering,etc. |

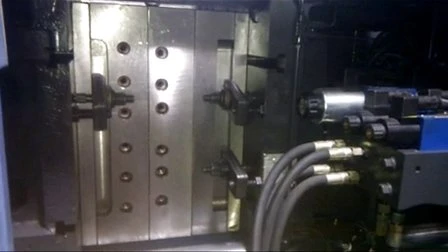

High- Speed CNC Milling MachinesLarge/Small Clamping MachinesHigh Speed Engraving MachinesDouble-Head EDM MachinesWire-cutting MachinesDeep Drilling Machines..........................

Our team will update the tooling processing to you once a week. QC Inspector: Professional tooling technology training and machine maintenance Self-inspection of tooling work piece and acceptance check made by quality department; Ratinal work shifts system and tooling control system.QC department should make product inspection within 24 hours and submit the testing report to relevant departments including the full range test and analysis for product size,appearance, injection techniques and Physical Parameter.

Taizhou Hongchuan Plastic Mould Co.,Ltd. is a leading manufacturer of large-scale injection molds based in China who is specialized in plastic products developing, injection mould design in Automotive Parts Moulds, Household Products Moulds, Home Appliances Injection Moulds, and daily necessities Moulds, and professional research. Our one-stop service includes mould design, manufacturing, and processing of semi-finished products.

With a complete sales network and customer channels established in Europe, South America, the Middle East, North Africa, Southeast Asia, and other regions, we have become a trusted supplier of injection molds worldwide.

Hongchuan team consists of experienced employees, including highly skilled designers, project managers, and fabrication technicians. We are committed to ensuring the success of all our projects and providing excellent customer service.Hongchuan Mould has the professional technical teams with advanced CAD/CAE/CAM/SOLIDWORK/ PRO-E/UG software assited project product analysis and mould deisgn, combined with efficient, high-precision processing equipments to achieve digital processing,grid quality control, on time delivery and excellent after-sales service. To maintain the highest standards of quality, we have imported advanced tooling equipment, including Sodick mirror EDM machines, wire cutting machines, 5-axis machining centers, and mold clamping machines.

At Hongchuan Mould, we welcome all friends to visit, guide, and negotiate business. We are dedicated to providing our clients with the best service and top-quality products.

| Mould for T1 | 55 days |

| Mould Deliver Time | 60 days |

| Mould Installation | Fixed |

| Mould HS CODE | 8480719090 |

| Package | Wooden Case, mould would be Fixed inside |

| Transportation | By Air or By Sea |

| Payment | T/T, CIF |

Q: Are you mould factory?

A: Yes, Hongchuan Mould is established in 2016 with our own worshop and office.To provide our customer a complete on-stop service.We have our own production flow from the procurement of steel preparations to five-axis milling machine, CNC tooling machine, lathe machine, fine carving machine, electric discharging machine, graphiting machine, slow wiring machine, wire cutting machine, etc., and then to mold installation.

Q: What kind of mould you can make?

A: Household parts mould : Plastic Basket Mould, Plastic Storage Box Mould, Chair &Table Mould, etc...

Appliance parts mould: Fan Mould,Air Conditioner Mould,Washing Machine Mould,TV Mould,Cooler Mould etc....

Automotive parts mould :Bumper Mould, Grill Mould,Interior Parts Mould,etc....

Thin-wall parts mould: Food Container Mould,Ice-Cream Mould, Cup Mould,etc..

Industry parts mould:Plastic Pallet Moulds, Dustbin Moulds,Crate MouldS, Transportation Moulds,etc... Pipe Fitting Mould: Collapsible Core Elbow Mould, PPR Pipe Fitting Mould,PVC Pipe Fitting Mould, Tee Mould,etc... .....................................We Customized the Plastic Injection Moulds according customers requirements.If you would like to make the Injection Moulds, Welcome!

Q: What about your payment terms?

A: 50% down payment in advance, and the balance will be paid before shipment.

Q: How long to finish a mould?

A: Mostly will be finished in 45 days, but some complex and big mould will spent more time. According to your order quantity,the delivery time will be different,but all based on the what kind of material that suitable for your mould solutions. We will be very surportive in delivery if client has unchangeable promotion plan.

Q: How long of the mould warranty period?

A: The mould warranty period for 1 year(Damage caused by human factors or accident are not within the the scope of warranty), and wearing parts will send to you for free.