Scooter PVC Wheel PP Toys Spare Part Plastic Injection Mold Mould

scooter pvc wheel pp toys spare part plastic injection mold mould 1,Professional mold making,100% of injection molds are

Basic Info.

| Model NO. | 1 |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Semi Fixed |

| Customized | Customized |

| Name | Scooter PVC Wheel PP Toys Spare Part Plastic Injec |

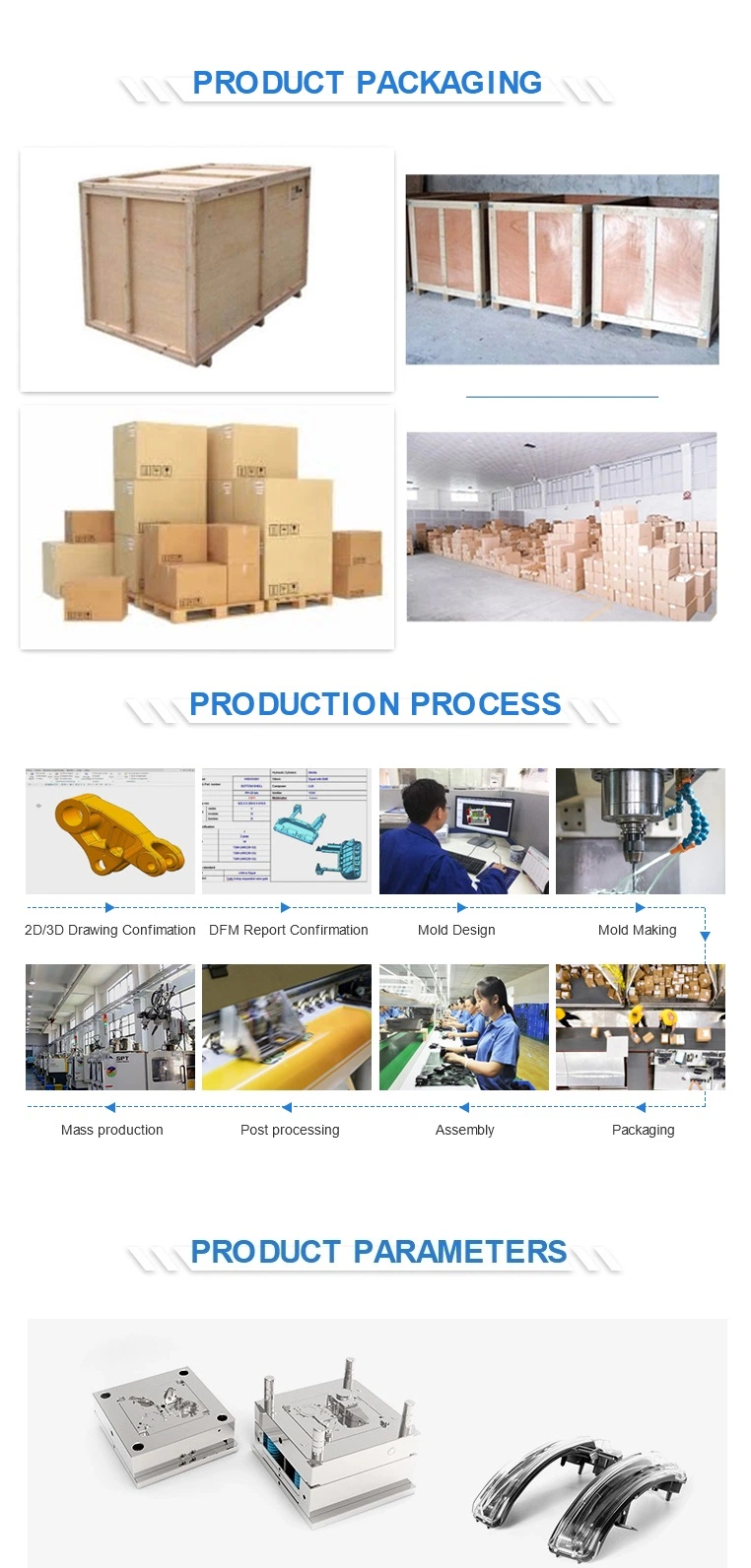

| Transport Package | Wooden Box |

| Specification | oem size |

| Trademark | oem logo |

| Origin | Made in China |

Product Description

scooter pvc wheel pp toys spare part plastic injection mold mould

| Process type Injection mold Number of mold parting surfaces Multiple parting surfaces Mold cavity Single or multiple Product materials PA, PA6, PA66, PC+ABS, PA46, PA+60%GF, PC, ABS, POM, PBT, TPU, TUR, PAMM, etc Part size According to customer requirements Part surface Polished / smooth, textured / ground Runner Cold / hot runner Mold life 2000000 beers Mold base LKM or according to customer requirements Mold material P20, 718H, NAK80, H13, 2738, NAK80, S136, SKD61, etc Drawing format JPEG, PDF, DWG, DXF, IGS, step, CAD Number of cavities Single cavity, multi cavity, according to customer requirements OEM / ODM Acceptable Starting quantity ± 0.01mm |

1,Professional mold making,100% of injection molds are customized for molds.

2,Professional team.The company has a professional product design and development technology team, which can design and produce various types of molds according to customers' ideas and requirements

3,Powerful equipment.Large CNC glass engraver machine center is a high technology equipment in which CAD/ CAM, CNC, mechanical design and manufacture, motor driver technology, and computer controlled optical surfacing ( CCOS) technology are integrated.

4,Neat environment.Clean working environment, for you to create high-quality mold.

Technological process

Business department→Design→review→CNC machining→Deep hole drilling→Wire cutting→EDM processing→Mold matching→Mold polishing→Mold test→Testing→Production

Send to us